Three dimensional scanning, imaging and printing

solutions for the everyday world.

Mission & Values

Imaging

2D/3D Imaging & Visualization

3D scanning captures the surface topology of a physical object as a collection of three dimensional co-ordinate data points that is sometimes referred to as a "point cloud". The scan processing software recognizes these data points as a series of “vertices” which when connected by straight lines, become “edges”. Three or more edges forming a closed loop become a “polygon”. Polygons sharing common edges form a “mesh”. The area bounded by the edges of a polygon becomes a “face”. Faces sharing common edges will mimic the “surface” of the scanned object.

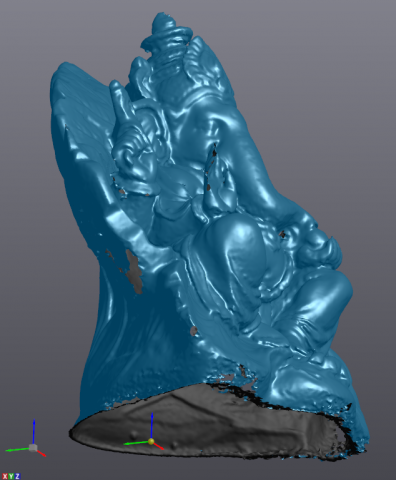

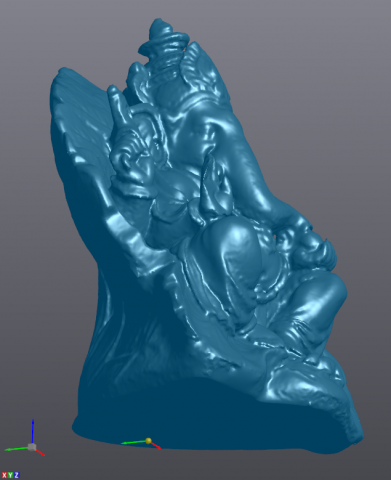

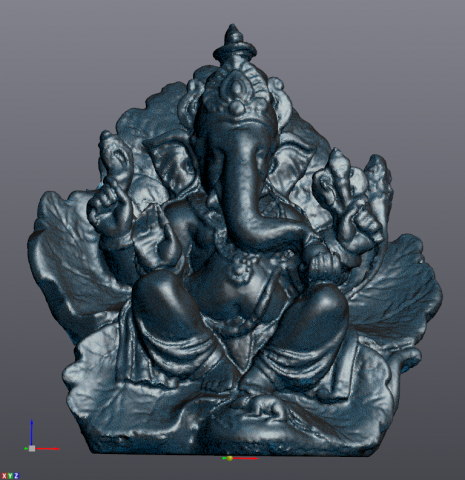

Sometimes, the scanning process will not be able to capture the entire surface topology of the target object or, it captures additional surface information from the environment surrounding the target object. When either of these situations occur, the raw scan data can be cleaned and the resulting polygon mesh supplemented and/or enhanced via post processing software. Scan data is usually captured at a resolution (distance between data points) that will faithfully reproduce the finest features of an object. This can result in a very large number of polygons in the mesh and an extremely large data file when saved. Decimating the mesh, reduces the overall polygon count by increasing the size of polygons on flatter surfaces thus reducing the number of polygons required in the mesh to cover same surface area with minimal loss of feature detail.

As-Scanned Scan cleaned and holes filled Mesh Model at scanned resolution Mesh model decimated

Click here to see the Ganesha sculpture in 3D.

Post processing may also entail the incorporation of parametric data (i.e. geometric entities, measurements, planes, cross sectional profiles, surface profiles…) for reverse engineering purposes.

Optionally, the corresponding surface texture (colour) data associated with this topology can be captured via the 3D scanner or derived from a series of 2D photographic images. This texture data can be superimposed upon the surface of the 3D model to create a very life-like virtual replica of the original scanned object.

The resulting 3D model can then be shared electronically 3D printed, saved as a Universal 3D format file and embedded into another document for interactive viewing and manipulation.